Batch Traceability System

Batch Traceability System (BTS) is defined as a communication network that enables a connected flow of data as well as an integrated view of an asset’s data across its lifetime through various isolated functional perspectives. This concept promotes transmission of the correct information, to the correct place, at the correct time.

In a manufacturing process, huge amounts of data are produced and analyzed to obtain efficiencies and reduce defects. According to LNS Research, it’s been confirmed that the Batch traceability System increases the supply chain efficiency by 16 percent. Moreover, this new trend of manufacturing enables delivery of new products to the market 20% faster.

A good number of manufacturers have yet to integrate the BTS into their systems. Another substantial application of the BTS is in corporate accountability. However, the depth to which government regulators can access pre-product data is still open for discussion. For instance, it is arguable that the Volkswagen emission menace could have been caught sooner had the government regulators accessed the Batch traceability System.

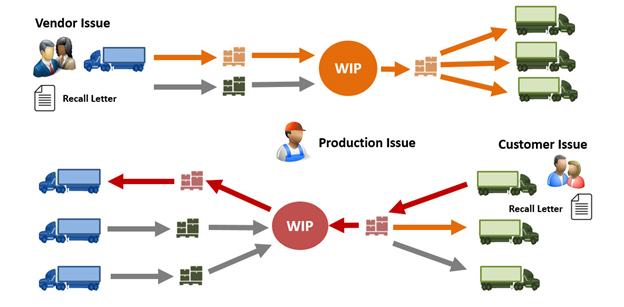

The Batch traceability Concept

The BTS is a simple concept – connecting digital information through product design, manufacturing, and inspection process of making a product. Manufacturing experts can easily view in real time how products pass through the manufacturing process, make the right decisions, operating effectively, as well as maintaining the right quality of products.